The Challenge

The customer owns one of the largest integrated paper mills in Malaysia. They manufacture high grade paper for domestic and export purposes. They recycle more than 375,000 metric tonnes of paper every year.

The Challenge

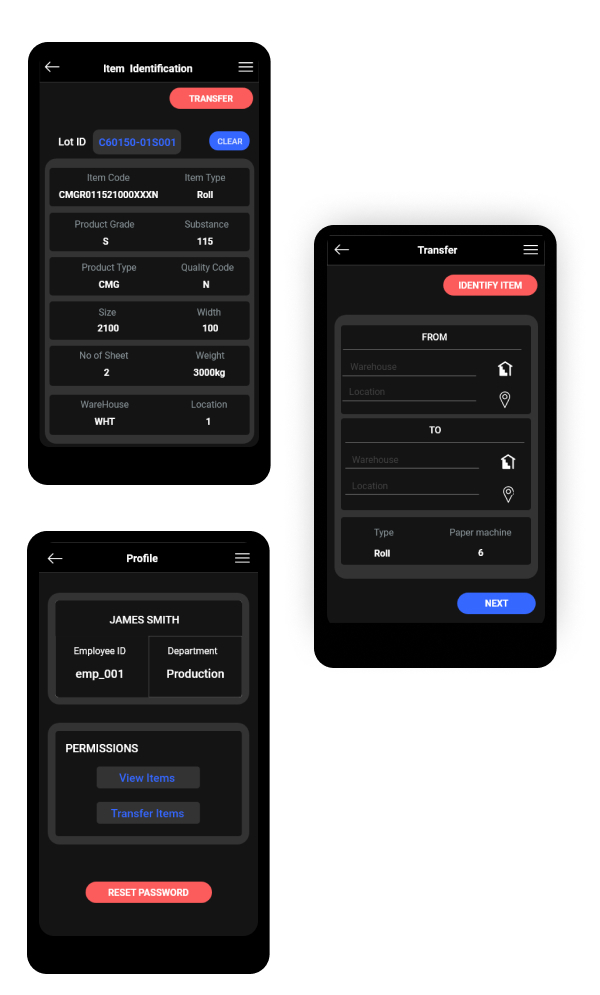

The customer wanted a mobile solution to track stock, products going in and out of a warehouse and that is transferred between warehouses. There is an ERP system, but during load and unloading information is written in paper and then manually loaded into the system. It was hard to know what is contained inside a carton especially when it is stored in a high place in a warehouse.

The Solution

The Spagylo Team proposed an integrated solution wherein an industrial grade mobile scanner running Android will work in tandem with the existing ERP. A microservices platform was built to interface between the app and the ERP application. Functionality was developed to scan any product and get related product information from the ERP system. A process was designed to scan any product lot when it arrives at or leaves a warehouse. The ERP system is updated in real time based on the recorded information from the scanners. Transactions like Warehouse transfer that are available in the ERP can now be triggered from within the app running on the barcode scanner.

Technology Stack

Node JS

Postgres DB

Android running on Motorola Barcode Scanner

LN ERP

The Results

The solution resulted in reduction in mistracked or lost inventory by 17%. The number of employees required to manage a warehouse reduced from 20 to 15. As change in inventory is recorded in real time, orders vs availability mismatch was reduced by 8%.